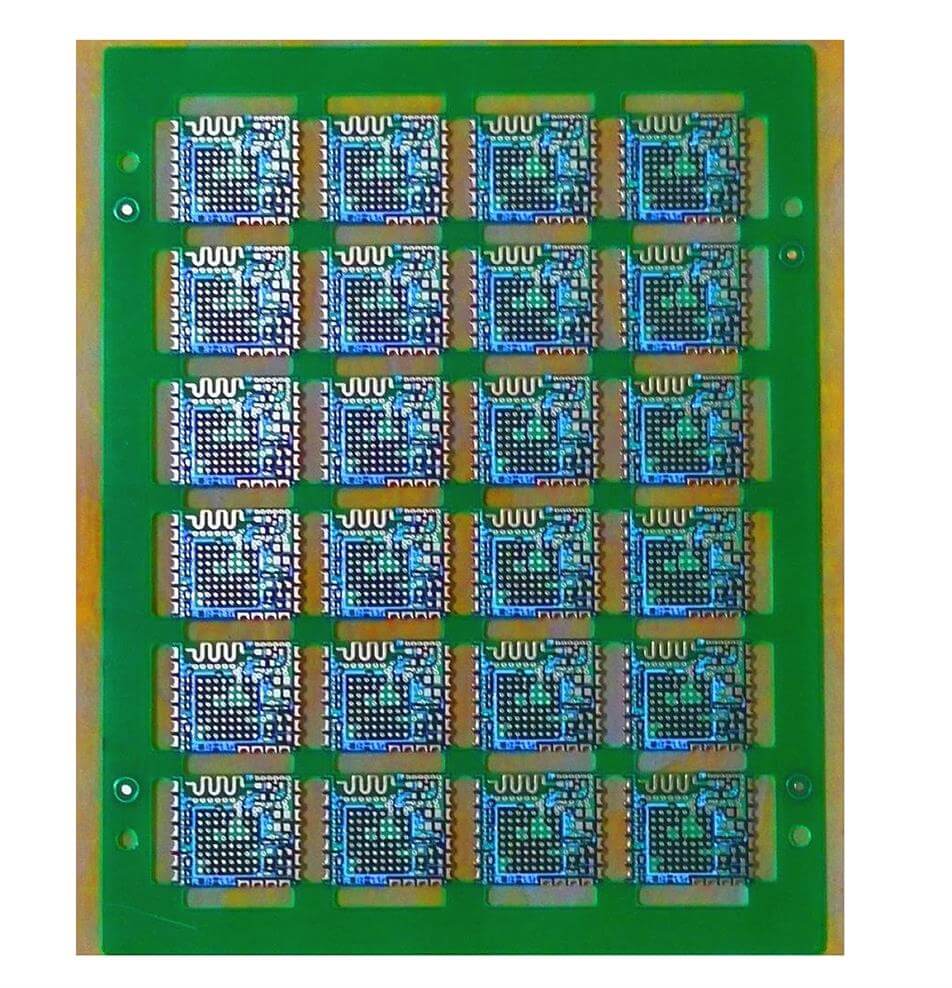

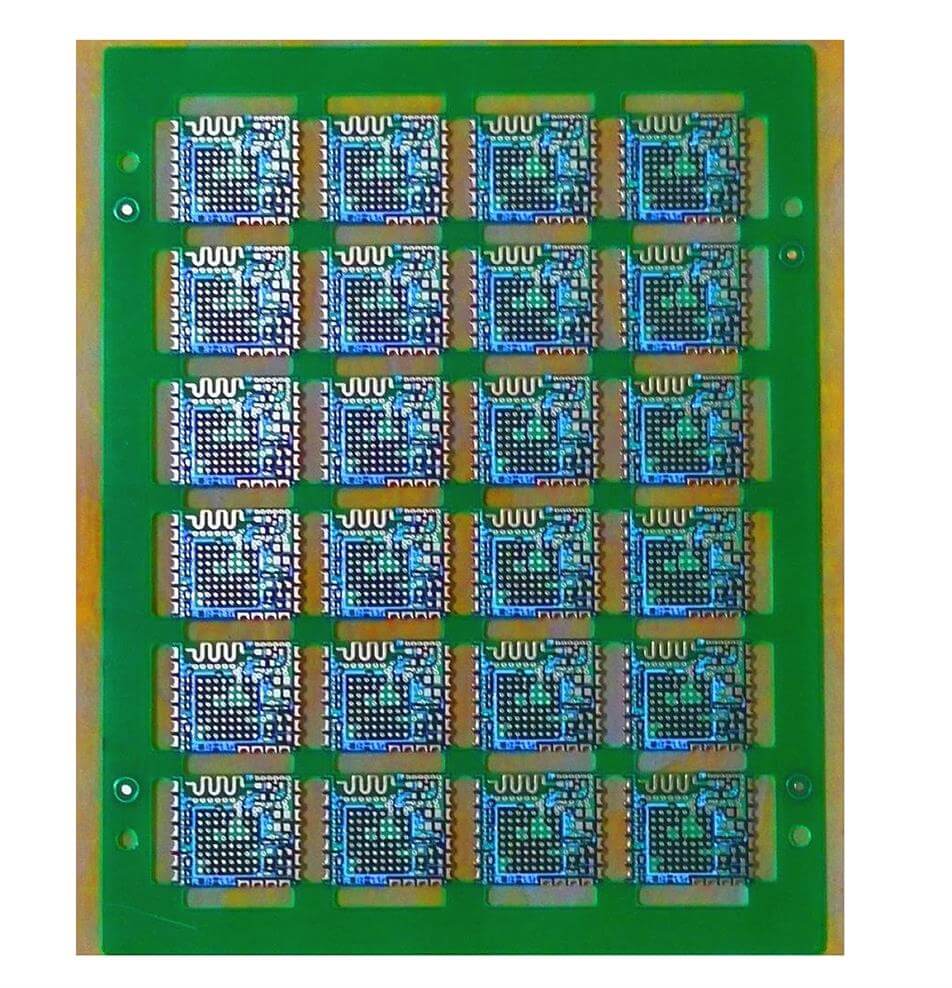

PCB prototype is divided into functional test and mass production confirmation

It is easy for many people to understand functional testing, but some people always think of omitting this step mass production confirmation, which will lead to serious problems. In fact, this step can not be omitted in the process of making, because once you omit this step, it is bound to have a great impact on the future, so now let's see why the step of PCB proofing confirmed before production cannot be omitted?

The reason is that this step of PCB proofing confirmed before mass production cannot be omitted, because there is a great process between sample and mass production.

1. Confirm before mass production that the samples and mass production of many PCB factories and chip factories are not produced by the same mold, so proofing before mass production can determine whether there is any problem with the production fixture and tools

2. A lot of functional samples, in order to ensure the delivery time pcbsmart.com ' target='_ The PCB Factory will put in more spare parts, even if it is scrapped a little more, it can also be delivered, but if the actual mass production scrap is large, the quality and delivery time can not be guaranteed

3. Both the PCB Factory and the PCB mounting factory will produce once according to the mass production form. They have an understanding of the utilization rate and the difficulties and problems in production. The optimization space can also be found in the confirmation before mass production, which can ensure the smooth mass production

4. The smoother the production, the better the natural quality and delivery time

Therefore, we still hope that you do not omit the PCB mass production confirmation prototype