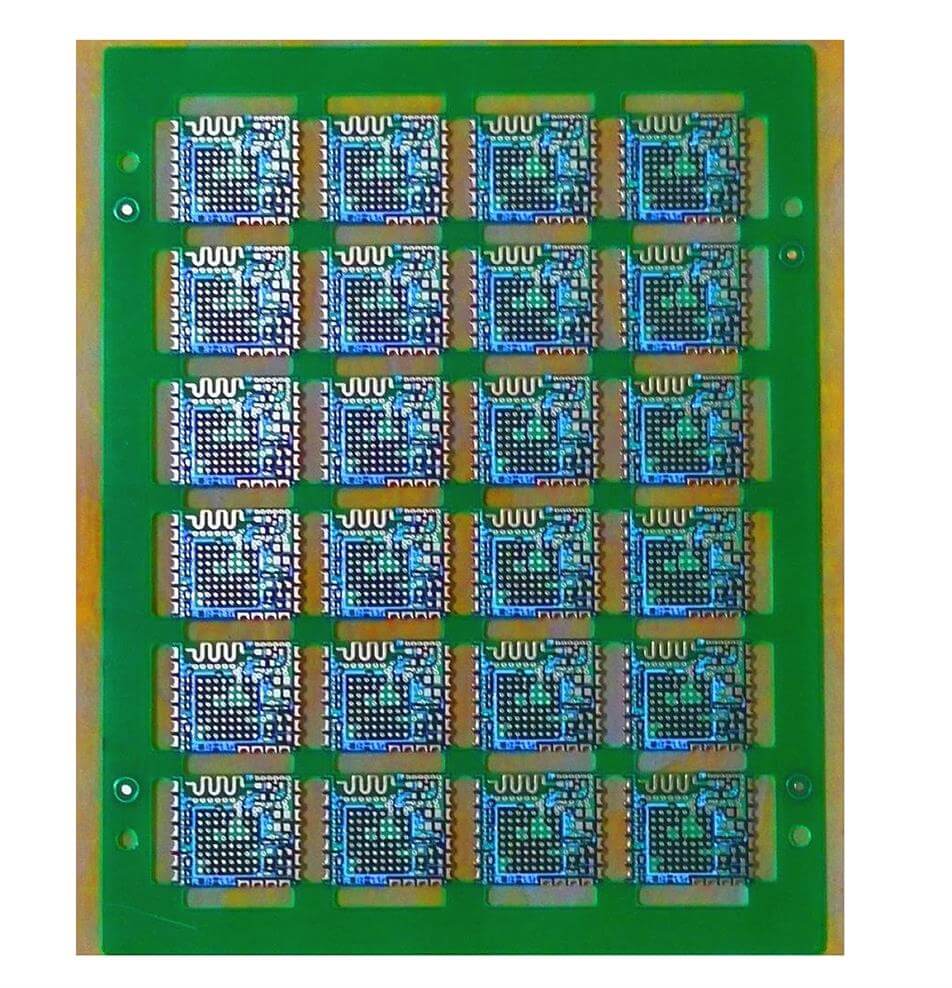

Cnc PCB

means the PCB is normal PCB, the PCB outline are made by CNC machine,1. what is CNC:

CNC is an automatic machine tool equipped with program control system. The control system can process and decode the program with control code or other symbol Bai instruction logically, so that the machine tool can move and process parts. CNC is the abbreviation of computerized numerical control, also known as CNC machine tools and CNC lathes. Hong Kong and the Pearl River Delta in Guangdong Province are called computer gongs.

It is mainly used for large-scale machining parts, and its processing methods include turning the outer circle, boring, turning plane and so on. Program can be written, suitable for batch production, production process of high degree of automation.

Since the first CNC machine tool was developed by Massachusetts Institute of technology in 1952, CNC machine tool has been widely used in manufacturing industry, especially in automobile, aerospace and military industry. Numerical control technology has developed rapidly in hardware and software.

2. The CNC advantages:

2.1 A large number of tooling is reduced, and complex tooling is not needed to process parts with complex shapes. If you want to change the shape and size of parts, you only need to modify the part processing program, which is suitable for the development and modification of new products.

2.2 The machining quality is stable, the machining precision is high, and the repetition precision is high, which can meet the processing requirements of aircraft.

2.3 In the case of multi variety and small batch production, the production efficiency is higher, the time of production preparation, machine tool adjustment and process inspection can be reduced, and the cutting time is reduced due to the use of the best cutting amount.

2.4 It can machine complex surface which is difficult to process by conventional method, and even can process some parts which cannot be observed.

The disadvantage of NC machining is the high cost of machine tools, which requires maintenance personnel to have a high level.

3. The three kind of mathod to do the PCB outline

3.1 Cut processing: using the Shearer to cut the shape of PCB, the processing can only process the straight line shape. This method is often used for pcb with many varieties, few quantities and low requirements on the overall dimensions. The disadvantage is that the accuracy is poor, and sometimes sandpaper polishing is required after processing.

3.2 Cut processing: Milling machine is the first choice for small and medium-sized batch processing by using CNC equipment and milling cutter. It can produce PCB with complex shape and high precision requirements without mould. Defects must allow the transition arc at the corner to be greater than or equal to the minimum radius of the milling cutter.

3.3 Punch processing: uses punch equipment and mold to process the shape of circuit board, with high processing speed and precision, which is suitable for mass production. However, the mold cost is high and it is difficult to switch the mold

So this the reply for CNC Pcb